Top Benchmark Precision Technologies: Revolutionizing Industries with High-Precision Solutions

Top Benchmark Precision Technologies: Revolutionizing Industries with High-Precision Solutions

Introduction: What are Benchmark Precision Technologies?

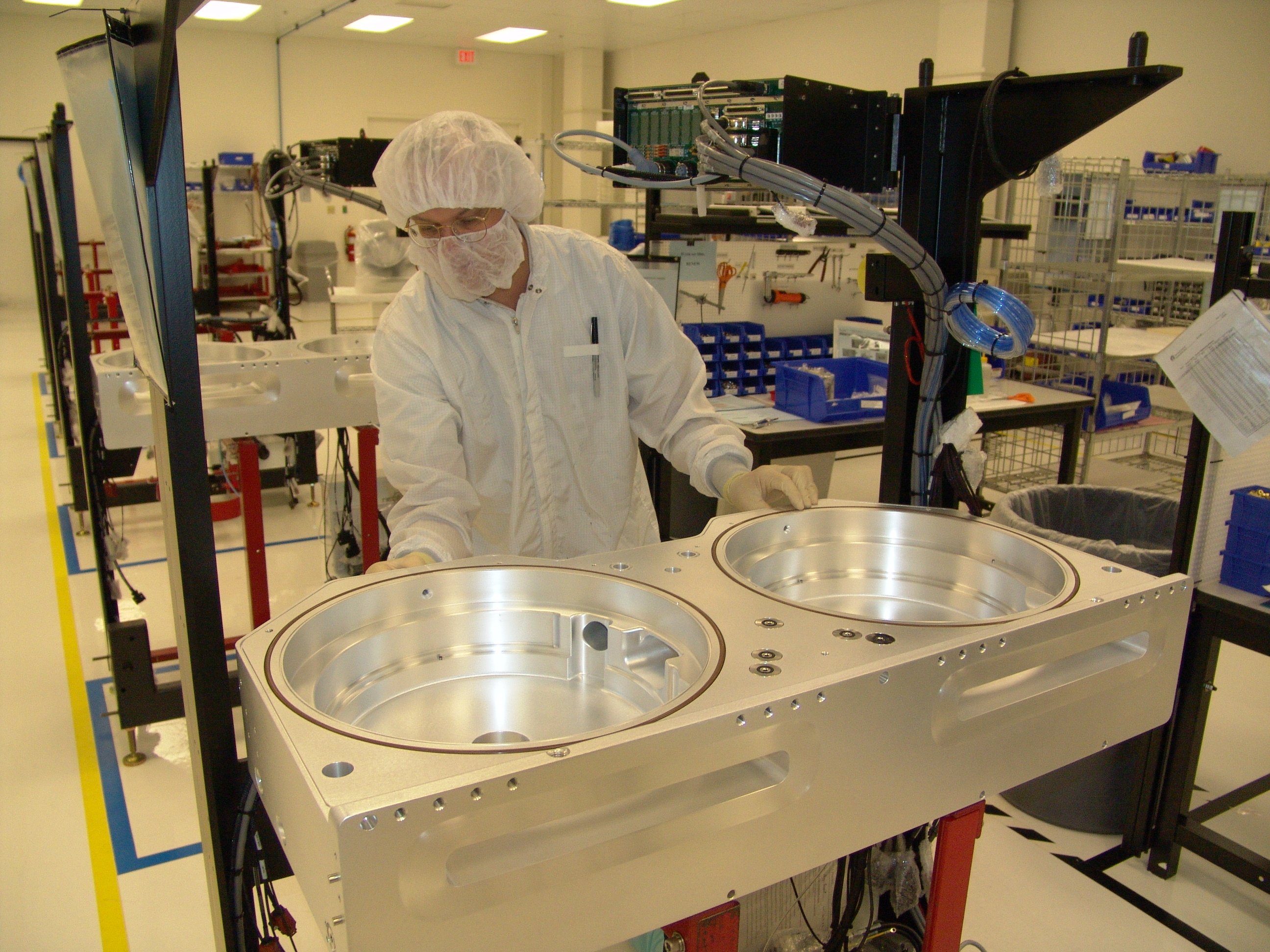

Benchmark precision technologies are tools and systems designed to measure, test, and improve the precision of industrial and technological processes. These technologies play a vital role in ensuring accuracy and efficiency, especially in sectors such as manufacturing, aerospace, automotive, and healthcare. The rise of precision measurement tools and benchmark testing technologies is driving advancements in automation and performance optimization.

The importance of these technologies cannot be overstated. As industries evolve and demand higher efficiency and lower margins of error, the need for benchmark precision technologies becomes even more critical. These innovations are revolutionizing production processes, minimizing waste, and maximizing throughput.

The Role of Benchmark Precision Technologies in Modern Industries

In today’s competitive landscape, industries rely on benchmark precision technologies to maintain a competitive edge. These technologies ensure that production processes are accurate, efficient, and consistent, improving quality control and minimizing errors.

-

Manufacturing: Precision technologies, such as CNC machines, 3D printers, and laser measurement tools, help improve product quality, reduce scrap rates, and optimize production cycles. These tools offer high-precision solutions that increase throughput while reducing costs.

-

Automation: In automation, precision technologies ensure that machines perform tasks with exact accuracy. From robotic arms in assembly lines to automated quality inspection systems, these technologies make processes faster, safer, and more reliable.

-

Healthcare: In the medical field, benchmark precision technologies help ensure the accuracy of diagnostic tools and equipment. These innovations enable more accurate medical imaging, robotic surgeries, and drug manufacturing.

Key Benefits of Benchmark Precision Technologies

Benchmark precision technologies offer a range of benefits that enhance efficiency, accuracy, and performance in industrial processes. Some of the key advantages include:

1. Enhanced Efficiency

By reducing errors and optimizing machine performance, precision technologies allow industries to work at higher speeds and with fewer resources. Automation systems powered by precision technologies ensure that tasks are completed faster and with minimal human intervention.

2. Improved Accuracy

Precision measurement tools are crucial in ensuring that every part and product is manufactured to exact specifications. With the help of these technologies, even the smallest deviations in manufacturing processes can be detected and corrected.

3. Cost-Effectiveness

While precision technologies require an initial investment, they ultimately save costs by reducing waste, scrap, and the need for rework. Industries can produce higher-quality products in less time, making operations more cost-effective.

4. Better Performance and Quality Control

Benchmarking allows companies to continuously assess and improve the performance of their equipment. By using benchmark testing technologies, companies can monitor machine health, performance, and precision to ensure that production systems are working at their best.

Types of Benchmark Precision Technologies

1. Precision Measurement Tools

Precision measurement tools, such as micrometers, calipers, and laser measurement systems, allow manufacturers to measure products with extreme accuracy. These tools ensure that every part produced meets the exact specifications required for optimal functionality.

2. Benchmark Testing Technologies

These technologies are used to assess and calibrate the performance of manufacturing systems. Benchmark testing methods help evaluate the precision of tools and machines and ensure that they meet industry standards.

3. Automation Technologies

Technologies like CNC machines and robotic arms are key components in automated manufacturing environments. They allow for high-precision tasks such as cutting, drilling, and welding, which require extreme accuracy to maintain consistent quality.

Top Benchmark Precision Technologies Revolutionizing Manufacturing & Automation

Several benchmark precision technologies are at the forefront of transforming manufacturing and automation processes. Let’s take a look at some of the most influential:

1. CNC Machines

CNC (Computer Numerical Control) machines have revolutionized manufacturing by enabling automated, highly accurate machining processes. These machines offer high-precision control, making them indispensable in industries such as aerospace, automotive, and medical device manufacturing.

2. 3D Printing

3D printing is a game-changer in industries that require rapid prototyping and customized production. Precision 3D printers use cutting-edge technologies to create objects with remarkable accuracy, which is essential for high-end manufacturing processes.

3. Laser Measurement Systems

Laser measurement tools are widely used in industries where accuracy is paramount. They offer non-contact, high-precision measurement capabilities, ensuring that even the smallest tolerances are maintained during production.

4. Robotic Automation Systems

Robots equipped with precision measurement tools ensure that tasks like assembly, packaging, and testing are completed with a level of accuracy and speed that would be difficult to achieve with human workers. These systems are increasingly used in manufacturing lines to improve productivity and reduce errors.

.jpg)

Real-World Applications of Benchmark Precision Technologies

1. Manufacturing

In manufacturing, precision technologies help improve the quality of products while minimizing defects. Automated precision tools like CNC machines and laser measurement systems help create parts that fit together perfectly every time, ensuring product consistency and quality.

2. Automotive

In the automotive industry, benchmark precision technologies are crucial for producing components that meet strict safety and performance standards. Technologies like robotic arms for assembly lines and laser inspection systems for quality control are widely used.

3. Healthcare

In healthcare, precision technologies have revolutionized medical imaging and diagnostic tools. MRI machines, CT scanners, and robotic surgery systems rely on benchmark precision technologies to ensure that medical procedures are as accurate and safe as possible.

Future Trends in Benchmark Precision Technologies

As industries continue to innovate, the future of benchmark precision technologies is shaped by emerging trends:

1. AI-Powered Precision Tools

Artificial intelligence (AI) is making its way into precision technologies, enabling systems to adapt and learn from data. AI-powered tools can enhance precision by predicting maintenance needs, improving performance, and ensuring optimal settings for production processes.

2. Robotic Automation

Robotic automation will continue to evolve, offering even higher levels of precision and versatility. With improvements in AI and machine learning, robots will be able to perform more complex tasks with greater accuracy.

3. IoT Integration

The Internet of Things (IoT) is becoming increasingly integrated into precision technologies, allowing machines and devices to communicate and share data. This connectivity will help monitor and adjust processes in real-time, leading to even greater accuracy and efficiency.

Challenges in Implementing Benchmark Precision Technologies

While benchmark precision technologies offer numerous benefits, their implementation can present challenges:

- Cost: The initial investment required for precision tools and systems can be high.

- Training: Employees must be trained to effectively use and maintain precision technologies.

- Integration: Integrating new technologies into existing manufacturing systems can be complex and time-consuming.

Conclusion: Why Benchmark Precision Technologies Are Essential for Industry Growth

Benchmark precision technologies are at the heart of industrial evolution, offering significant improvements in efficiency, accuracy, and performance. By embracing these technologies, industries can streamline operations, reduce waste, and deliver high-quality products at competitive prices. As we move into the future, precision technologies will continue to drive innovation and growth across a wide range of industries.

Investing in precision technologies today will pave the way for smarter, more efficient manufacturing and automation in the years to come. Start exploring how these technologies can transform your industry and stay ahead of the curve.